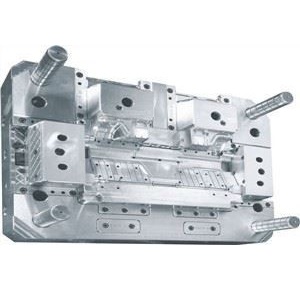

Plastic housing mold12

Short Description:

Mould material: 2344, 8407, P20, S7, etc.

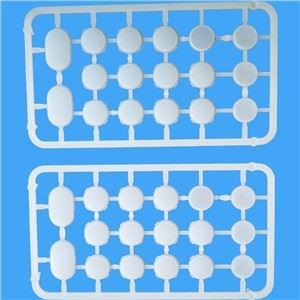

Product: Small Plastic Parts Cavity number: 1 to 48

Cavities Mould life: 100K to 1

Million shots Plastic material:PTFE, PEEK, polymer, PVDF, PVC, CPVC, PPS, ETFE, polypropylene and PFA etc.

Application: Small Parts Plastic Injection Mold For Automotive,…

Description

Mould material: 2344, 8407, P20, S7, etc.

Product: Small Plastic Parts

Cavity number: 1 to 48 cavities

Mould life: 100K to 1Million shots

Plastic material:PTFE, PEEK, polymer, PVDF, PVC, CPVC, PPS, ETFE, polypropylene and PFA etc.

Application: Small Parts Plastic Injection Mold For Automotive, Appliance, Electrical, etc

Features of plastic housing molds:

mould structure is required very stable, to ensure long term continuously mass production.

the gate position and runner is very important to get very beautiful surface and appearance samples.

mould structure is complicate, in order to meet the functional requirements of the plastic product.

requires many complex lifters and sliders or double lifters & sliders to release undercuts.

many other plastic components are assembled into them, so dimensions control and warping is very important.

texture and polish is extremely important to get the perfect plastic parts, many parts are mirror finishing SPI A1

JS MOULD Mold is a proffesional plastic injection moulds & injection molding manufacturer. . Our production sites have been accredited the certification of ISO 9001, Available with maximum1300 ton clamping force. Various plastics include PTFE, PEEK, polymer, PVDF, PVC, CPVC, PPS, ETFE, polypropylene and PFA. Industries served include aerospace, chemical and food processing, marine, medical apparatus, military/defense, pharmaceutical and nuclear

our resource also can provide Spray painting,pad printing ,Silkscreen,,ultrasonic welding,Laser Etching to ensure you complete solution.